Injection Blow Molding

technologies

What is Injection Blow Molding?

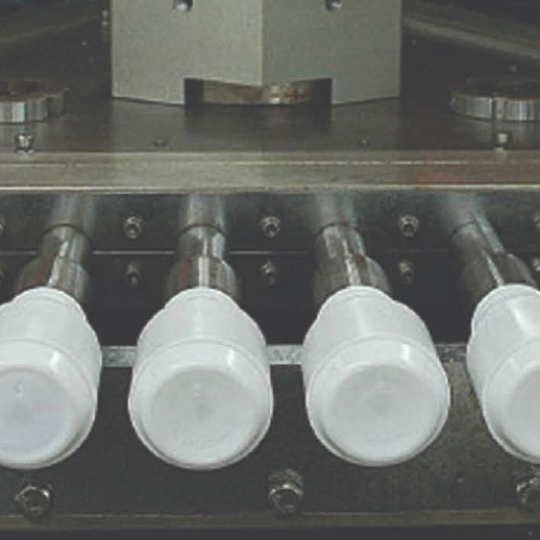

Injection blow molding is a specialized plastic manufacturing process used to create hollow, seamless containers. In this method, a plastic preform is first injection molded, creating a precursor with a neck finish and a hollow center. The preform is then transferred to a blow molding machine where it is heated and inflated with compressed air to take on the shape of the final container’s mold cavity.

The injection blow molding (IBM) process produces billions of plastic containers each year, ranging in size from 1 ml to 2 liters. These containers meet exacting standards of consistent weight, volume and tolerance, and are popular for pharmaceuticals and toiletries to automotive and household use.

IBM Process & Bottle Characteristics

- Virtually no scrap

- No trimming

- Virtually no waste

- Minimal auxiliary equipment required

- Exact neck dimensions

- Thick, even walls

- Parting lines nearly invisible

- Variety of different finishes are possible

Typical Products For Injection Blow Molding

Jars

- Made in a wide variety of materials

- No secondary trimming is required when making the neck finish

Ovals – Cylinders & Boston Rounds

- HDPE, LDPE, PP

- Up to 24 cavity molds from 10-15 second cycles

Liquor Bottles

- Thick walls mimic the look of glass

- Intricate design

Pill Bottles

- PP, HDPE, LDPE and PS

- Can be designed with complicated injected neck finishes for Child Resistance or pilfer-proofing

- Neck finish is excellent for barrier seals against moisture with a plug seal closure

- Very flat for tamper foil application

Roll-On Deodorant

- PP and HDPE

- Close tolerance of the injection molded ball seating allows for an even application of the deodorant product

Specialty Items

- Lab ware

- Custom shapes

- Food coloring/dropper bottles

Advantages and Disadvantages of Injection Blow Molding

| ADVANTAGES |

| Virtually no scrap |

| Excellent gram weight control |

| Excellent material processing capability options |

| Good material distribution consistency |

| Excellent finish dimensional control |

| High cavitation capability with smaller bottle sizes – up to 32 cavity tool sets |

| Lower price for high volume, smaller size items |

| Friendly for downstream operations like decoration |

| Accommodates snap-in plugs, fitments, dispensing spouts & orifice reducers |

| DISADVANTAGES |

| Longer tooling development lead times |

| Unit cavity ahead is almost always required |

| Higher mold equipment costs |

We are here for you. How can we help?